EZCNC Router-MG Series

Ezletter CNC Router MG Series is based on MD series redesigned with a high-quality dual-screw drive Eyecut routering machine. It has contained to all the features and advantages of the MD series, the whole machine lightweight, stable performance, perfect processing quality. The machine is equipped with Eyecut system for fast cutting inkjet panel.Control system can be used by customers to choose.

|

Base Frame: 1.The gantry is made of 300mm*200mm steel tube that has internal stiffeners. The gantries are welded, stressrelieved, and precision machined. The gantry has been engineered to provide a smooth, vibration free cut. |

|

Dual Ballscrew with Driven Nut: Dual Ballscrew with Driven Nut in X-Axis. |

|

Test Each machine: EZLETTER is not only used to detect the linear accuracy, but also the geometric accuracy of the machine. So you can fully believe that the machine you purchased is accurate and has been calibrated correctly. |

|

Linear Bearings and Ball Screw: 1.25 mm ball linear bearing profile rails; 2.32mm ball screw,the size is about 1.3times of normal modle; 3.High rigidity and top load capacities in all load directions. |

|

Z axis Ball Screw Assembly: The 25mm ball screw is supported by precision dual angular contact ball bearings in a steel housing.The servo motor with brake system link to ballscrew by a R+W couple from Germany. |

|

AC Digital Servo Drives: Yaskawa Sigma servo amplifiers have all-digital architecture with 32-bit microprocessor logic, high speed ASIC current-loop control, and IGBT power sections. These drives seamlessly integrate position, velocity, and torque loops to provide uncompromised tracking accuracy, smoothness and reliability. |

|

Auto Tool Changer: The MD-ATC series machine is available with an optional 4-6 position linera tool changer. All ATC systems come standard with Automatic Tool Calibration and the tool change routines are built into the controls simplifying integration to your favorite CAM software. An Automatic Tool Change solution will help you reduce job times, improve accuracy, and reduce setup errors. |

|

Spindle System 1.Adopt in YASKAWA or Delta Inverter |

|

High speed chuck and nut with dynamic balance: 1.Adopt high speed chuck and high speed nut , which is suitable for high speed machining; |

|

Drag chain system: The cost of using igus flexible cable and drag chain in Germany is obviously much higher than that of ordinary cable and drag chain. But it can guarantee the reliability of the machine. The machine tool is in motion all the time, and the cable is twisted repeatedly. The ordinary cable is easily broken when using it, and there will be inexplicable faults, and it is very difficult to maintain. We use a totally enclosed drag chain system to ensure the absolute safety of the cable. |

|

Electrical components: Abb, Schneider, Wago and other imported brands are used for electrical components in the cabinet. |

|

Whole protective cover: The whole machine adopts the flexible protective cover made of imported materials to protect the screw rod and guide rail, which is not easy to be stained with chips and affect the accuracy or damage. |

Option

| HandWheel | Move the machine by hand wheel |

| HandHeld Keypad | 30 key keypad with VFD display |

| Mister | Adapt to cutting the acrylic and aluminium ect. |

| 3D Laser scan | Scan 3D part |

| HSC | HSC (High speed cut) |

| Atuo lubricator | For the moving parts lubration |

| Spindle water cooler | Cooling the spindle when cutting for a long tiem and with heavy load |

|

Ezletter developed EZCNC Controller System with its own intellectualEzletter developed EZCNC Controller System with its own intellectualproperty right. We can provide customers with customizable products andservices. All the functions are integrated in the graphical keypad. The 30buttons can complete more than one hundred of functions. EZCNC Controller is a CPU+DSP+FPGA control system. The specialdigital processing chip combined with the optimization algorithm makes themachining precision and speed reach the leading level of the internationalsimilar products. |

|

EZCNC Feature: 1) Easy to operate, graphical keypad. 2) Multi home set, 6 fast home and 3 permanent home with z axis coordinates 3) High Precision find limits, Capture home rapidly 4) Six jog mode. Step move and continues move, absolute move and relative by input value. 5) Park in the max position 6) Auto Surface 7) Max cut depth protection, by auto surface block or input value 8) Look ahead, unlimited for the size of job file,G-code inspection before machining 9) Feed override real-time,spindle speed adjustment real-time 10) Network DNC, USB disk,2GB hard disk inside 11) Can control four to eight axes 12) Spindle Warm-Up 13) Modbus communicate with inverter, real time display spindle power and torque 14) Linear tool changer, Carrousel tool changer, servo tool changer and multi-head spindle 15) ATC Collision Detection 16) Auto tool calibration, tool length compensation 17) Tangential knife 18) Dust tracker 19) Rigid tapping 20) Linear interpolation, circular interpolation, helical interpolation 21) Approximate restart and Breakpoint continues,Pause and move and resume,and surface canbe adjusted in the pause. 22) Electronic saw function: Line, rectangle and circle 23) High strength casting aluminum shell with good EMC 24) Integrated high brightness OLED screen and emergency stop on the Keypad 25) Get the center from two point , three points or four points 26) Gantry axis 27) Dry running mode, preview tool path 28) High speed double pulse output. 29) Laser set surface, Laser scan, Laser tracker |

| Model | MG1313 | MG1325 | MG1530 | MG2030 |

| Table Size | 1270mm x 1270mm | 1270mm x 2540mm | 1500mm x 3000mm | 2000mm x 3000mm |

| X-Dual Ballscrew | Yes | |||

| Servo | Yes | |||

| Axes | 4 | |||

| Z clearance | 150mm | |||

| Vacuum zone | 2 | 4 | 4 | 6 |

| Spindle power(KW) | HSD9.6ATC | |||

| Spindle speed | 24000rpm | |||

| Collect | ISO30 ER32 | |||

| Auto surface | Yes | |||

| Gantry Axis | Yes | |||

| Speed(X,Y Axis) | 30m/min | |||

| Speed(Z Axis) | 15m/min | |||

| Weight(KG) | 1700 | 2200 | 2700 | 3200 |

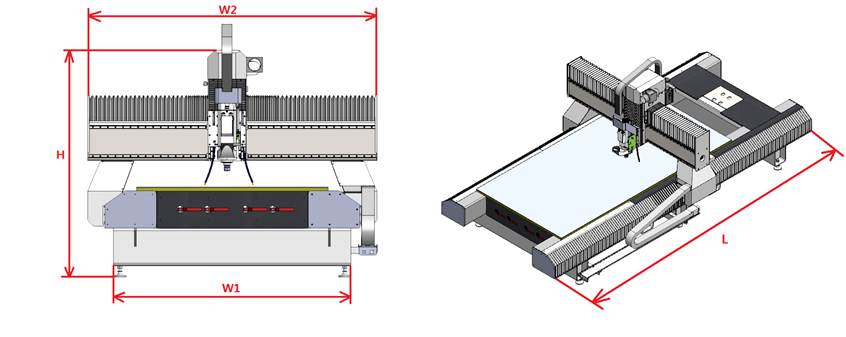

| Model | L | W1 | W2 | H |

| MG1530 | 4600 | 1890 | 2304 | 2015 |

| MG1325 | 4012 | 1852 | 2154 | 2015 |

| MG1313 | 2342 | 1746 | 2564 | 2015 |

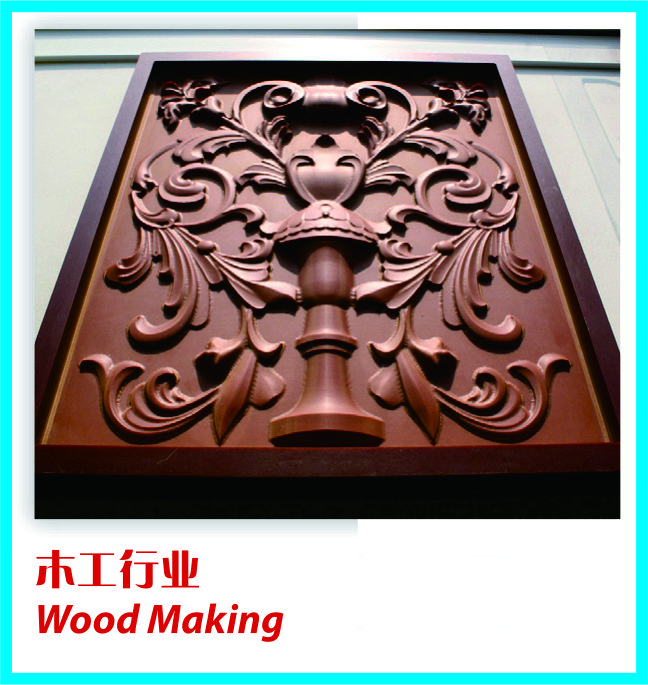

| Aluminum plate and aluminum plastic plate are slotted. |

| Leather mold, ceramic mold production. |

| 3D surface - metal or non-metallic, composite, artificial marble carving. |

| Wood carving, acrylic panel (TV, DVD and other acrylic panels) production. |

| Acrylic display shelf, acrylic products production. |

| The carving, cutting and relief of advertisements. |

| Cutting and drilling of aluminum plate and aluminum honeycomb plate |